Sustainable

GRP Pipe Systems

Engineered in Australia for

generations of reliable service

High-performance GRP solutions – from concept to completion

Amiblu delivers complete GRP (glass-fibre reinforced plastic) solutions – combining advanced pipe systems, expert engineering, and on-site support.

Our pipes, joints, fittings, tanks, and manholes are corrosion-resistant and exceptionally durable. They ensure reliable, long-lasting performance across sewer and drainage, irrigation, hydropower, drinking water, and industrial applications.

Each project benefits from our engineering expertise – from product design and customisation to installation support, on-site supervision, and practical guidance during execution. This comprehensive approach ensures every solution performs at its best for generations to come.

Amiblu offers a wide range of GRP pipe systems for various infrastructure needs. Our portfolio includes non-pressure pipes for gravity sewers and drainage, pressure pipes for water, hydropower, and industrial use, durable jacking pipes for trenchless installation, and non-circular profiles for relining aging urban networks.

All Amiblu GRP pipe solutions feature a proven jointing system that ensures reliable performance throughout their entire service life and allows easy transitions to other materials or accessories. Pipes and couplings can be supplied separately or pre-assembled for quick installation. Laminated field joints are available in both uniaxial and biaxial designs.

Amiblu offers a wide range of GRP fittings – both standard and custom-made – for pressure and non-pressure applications. With more than 200,000 standard designs, our fittings are corrosion-resistant, highly durable, and engineered for reliable performance in every system

Amiblu GRP tanks and manholes are built for strength, durability, and easy installation. Corrosion-resistant and watertight, they provide reliable solutions for storage, access, and inspection in sewer, drainage, and water networks, ensuring long-lasting performance with minimal maintenance.

Partnering with Amiblu means sharing responsibility for every stage of a project. Our team supports you from initial design to final commissioning, offering product development, application engineering, and tailored solutions for specific site conditions. Backed by more than 60 years of R&D in GRP technology, Amiblu delivers systems that are efficient, reliable, and built to last.

Amiblu supports your project with expert on-site supervision and installation guidance. From the first trench to final commissioning, our specialists ensure that complex installations run smoothly, safely, and efficiently – delivered on time and to the highest standards.

Applications

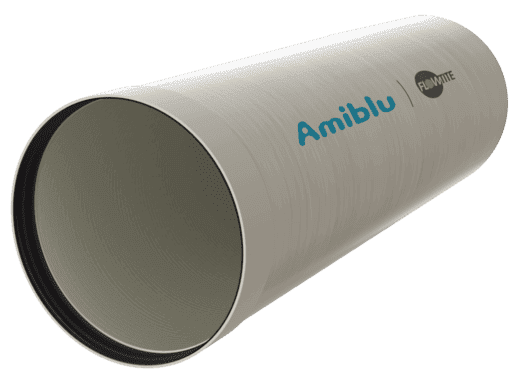

Our Manufacturing Technologies

Amiblu’s Flowtite technology uses advanced continuous filament winding to create lightweight yet exceptionally strong GRP pipes. Precise fibre placement ensures exceptional durability and corrosion resistance, delivering reliable, long-lasting pipes for modern infrastructure.

| Diameter Range (DN) | 300 to 3000 mm |

|---|---|

| Pressure (PN) | 1 to 35 bar |

| Stiffness (SN) | 5,000 to 1,000,000 N/m³ |

| Nominal lengths | 1, 2, 3, 6, 12 and 13 m |

Amiblu’s Hobas technology uses a fully computer-controlled centrifugal casting process to build GRP pipes layer by layer from the outside in. This creates perfectly circular, uniformly thick pipes with outstanding strength, stability, and heat resistance, delivering reliable performance even under high loads and demanding conditions.

| Diameter Range (DN) | 300 to 3000 mm |

|---|---|

| Pressure (PN) | 1 to 35 bar |

| Stiffness (SN) | 5,000 to 1,000,000 N/m³ |

| Nominal lengths | 1, 2, 3, 6, 12 and 13 m |

Amiblu’s NC Line technology uses controlled filament winding on non-circular mandrels to build dense, shape-specific GRP profiles. Precise layering of resin, glass fibers, and sand yields high bending strength, chemical resilience, and structural stability – ideal for relining or replacing old sewers, culverts, and complex channels.

| Diameter Range (DN) | 300 to 3000 mm |

|---|---|

| Pressure (PN) | 1 to 35 bar |

| Stiffness (SN) | 5,000 to 1,000,000 N/m³ |

| Nominal lengths | 1, 2, 3, 6, 12 and 13 m |

Flowtite Technology

Amiblu Australia proudly manufactures Amiblu Flowtite GRP pipes at our facility in Lonsdale, South Australia, employing over 80 Australians and working with local partners to support regional growth. With more than 1,500 km of pipes produced for major infrastructure projects, we serve both the Australian and New Zealand markets.

Following the 2024 acquisition of RPC Pipe Systems and Global Pipe by Amiblu, we’ve united decades of local expertise with global GRP leadership – delivering manufacturing, technology, and service under one trusted brand: Amiblu Australia.

Amiblu GRP pipe projects across Australia

A 2-km Amiblu GRP pipe network secures cooling for the 390 MW Atinkou power plant, strengthening Côte d’Ivoire’s role as a regional energy hub.

Amiblu’s innovative GRP profiles enhance Wrocław’s sewage infrastructure, improving hydraulic safety, durability, and resistance to extreme weather.

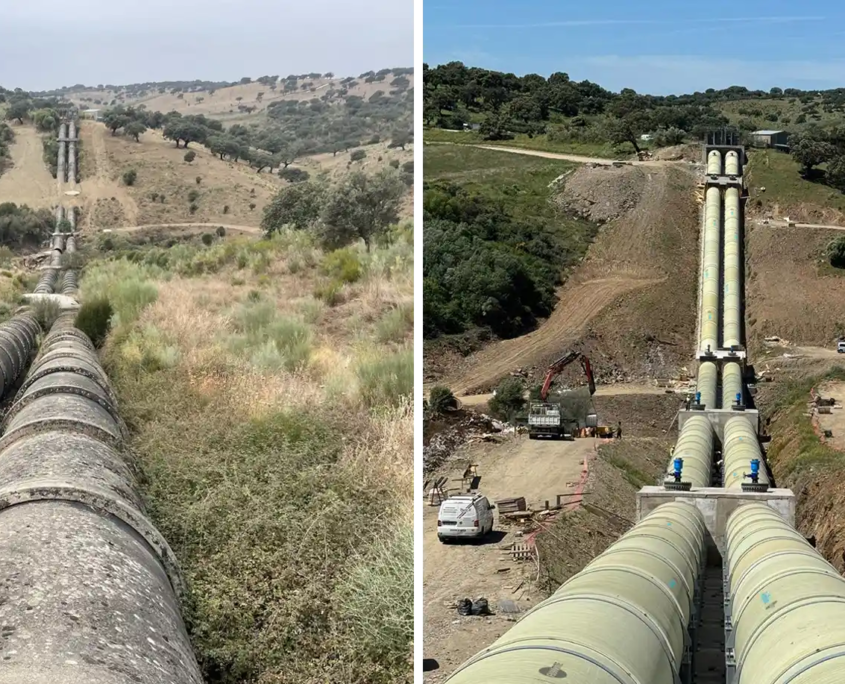

With the installation of Amiblu GRP pipes DN 3000, the Irrigation Community on the right bank of the Alagón River secures water supply for 15,600 hectares and strengthens the resilience of local agriculture.

Fulda: Regenrückhaltebecken ersetzt, 1,2 Mio. Euro und 14 Monate Bauzeit eingespart

In Senegal’s capital city Dakar, a critical infrastructure upgrade is underway to address decades of deterioration in the Hann-Fann sewer collector.

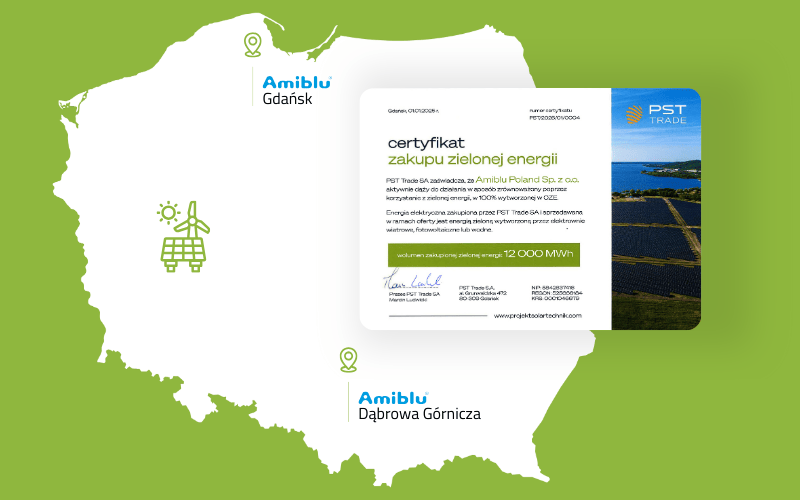

Our activities

The greenest pipe is the one you don’t need to replace

Learn more about how GRP outperforms other materials and how Amiblu is tackling the world’s water crisis.

Contact Amiblu Australia

Use the contact form for enquiries about products, technical info, installation, or expert advice – we’ll connect you with the right specialist.

Amiblu Pipe Systems Pty Ltd

11 Christie Road, Lonsdale,

5160, South Australia, Australia

Amiblu Australia Pty Ltd

25 Beaumaris Parade, Highett,

3190, Victoria, Australia